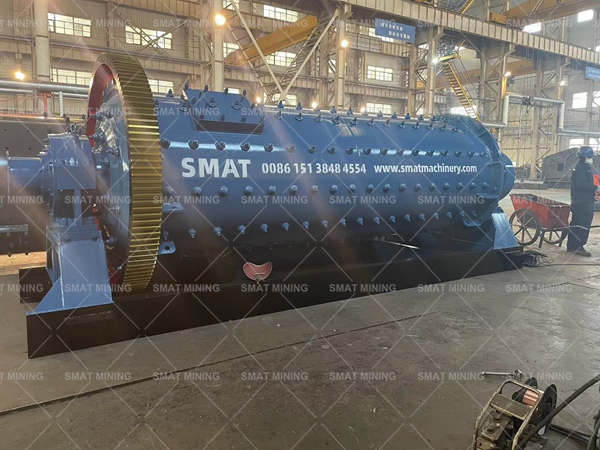

Wet ball mill are essential for fine grinding of ores, ceramics, and slurry chemicals. Compared to traditional designs, our ball mills offer higher efficiency, lower energy consumption, and longer service life. They are suitable for mineral processing and other applications.

Max Ball Load(t)

Feeding Size(mm)

Capacity

| Model | Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging Size(mm) |

Capacity (t/h) |

Power (KW) |

Total weight (t) |

|

| φ900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 | |

| φ900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 | |

| φ1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 | |

| φ1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 | |

| φ1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 | |

| φ1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 | |

| φ1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 | |

| φ1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 | |

| φ1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 | |

| φ1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 | |

| φ1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 | |

| φ1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 | |

| φ2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 | |

| φ2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 | |

| φ2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 | |

| φ2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 | |

| φ2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 | |

| φ2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 | |

| φ2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 | |

| φ2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 | |

| φ2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 | |

| φ2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 | |

| φ2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 | |

| φ3200×4500 | 18 | 65 | <25 | 0.074-0.4 | 按工艺定 | 630 | 149 | |

| φ3600×4500 | 17 | 90 | <25 | 0.074-0.4 | 按工艺定 | 850 | 169 | |

| φ3600×6000 | 17 | 110 | <25 | 0.074-0.4 | 按工艺定 | 1250 | 198 | |

| φ3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 | |

| φ4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 | |

| φ4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 | |

| φ4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 | |

| φ4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 | |

| φ5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 | |

| φ5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 | |

| φ5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 | |

Wet ball mills are essential for fine grinding of ores, ceramics, and slurry chemicals. Compared to traditional designs, our ball mills offer higher efficiency, lower energy consumption, and longer service life. They are suitable for mineral processing and other applications.

SMAT Wet Ball Mill Product Line

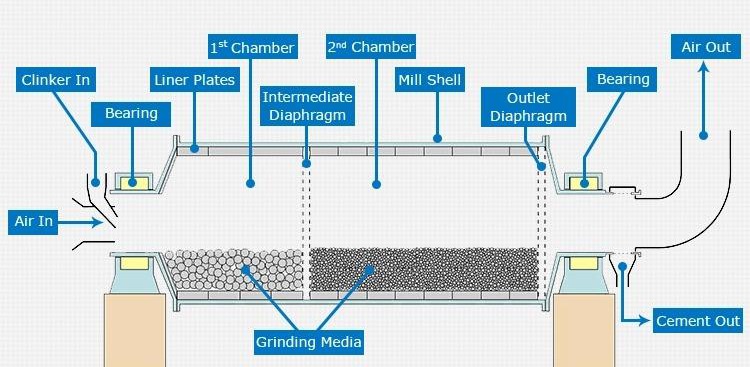

Grate Ball Mill

Principle:Grate ball mills have a grate lining (grate plate) installed on the discharge side. The ground slurry is lifted by the grate lining through a fan-shaped chamber leading to the discharge port to a level above the discharge port, where it is discharged from the mill. Discharge: The upper limit of the particle size of the grate ball mill's product is generally 0.2-0.3mm, so it is often used in the first stage of grinding.

Overflow Ball Mill

Principle: Overflow ball mills do not have a grate liner installed on the discharge side. Instead, spiral blades running in the opposite direction of the mill's rotation are installed on the inner surface of the hollow shaft bushing at the discharge end. This prevents water balls or coarse ore lumps from being discharged along with the slurry. Overflow ball mills discharge by gravity when the slurry itself rises above the bottom edge of the hollow shaft bushing.

Discharge: The particle size of the product of overflow ball mills is generally less than 0.2mm, making them suitable for the second stage of grinding.

Wet Process Ball Mill Solutions

Mineral ore processing, Metal powder slurry, Industrial chemical processing

We specialize in both dry and wet process ball mills engineered for optimal performance across industries. Our solutions are customized for your specific material characteristics and production requirements.

✔ Material-Specific Engineering - Optimal solutions for dry powders or slurry processing

✔ Flexible Configuration - Convertible designs for changing production needs

✔ Energy Optimization - Advanced drive systems reduce power consumption

✔ Global Support - 24/7 technical assistance for all grinding applications

Why Choose Our Ball Mill?

Superior Grinding Performance:

Our ball mill ensures efficient and uniform grinding of materials, delivering consistent particle size and quality.

Versatility for Multiple Applications:

Ideal for grinding materials like ore, cement, ceramics, and chemicals, our ball mill adapts to a wide range of industries and applications.

Durable and Reliable Design:

Built with high-quality materials and heavy-duty components, our ball mill is designed to withstand harsh operating conditions, ensuring long-lasting performance.

Low Maintenance and Operational Costs:

With a simple design and minimal moving parts, maintenance is quick and hassle-free, reducing downtime and saving you money.

Energy-Efficient Operation:

Our ball mill is optimized for low energy consumption, helping you reduce operational costs while maintaining high efficiency.

Customizable Solutions:

We offer tailored configurations, including size, capacity, and speed adjustments, to meet your specific grinding needs, ensuring the perfect fit for your operations.

Safe and Smooth Operation:

Equipped with safety features like emergency stop buttons and protective guards, our ball mill ensures a safe working environment for operators.

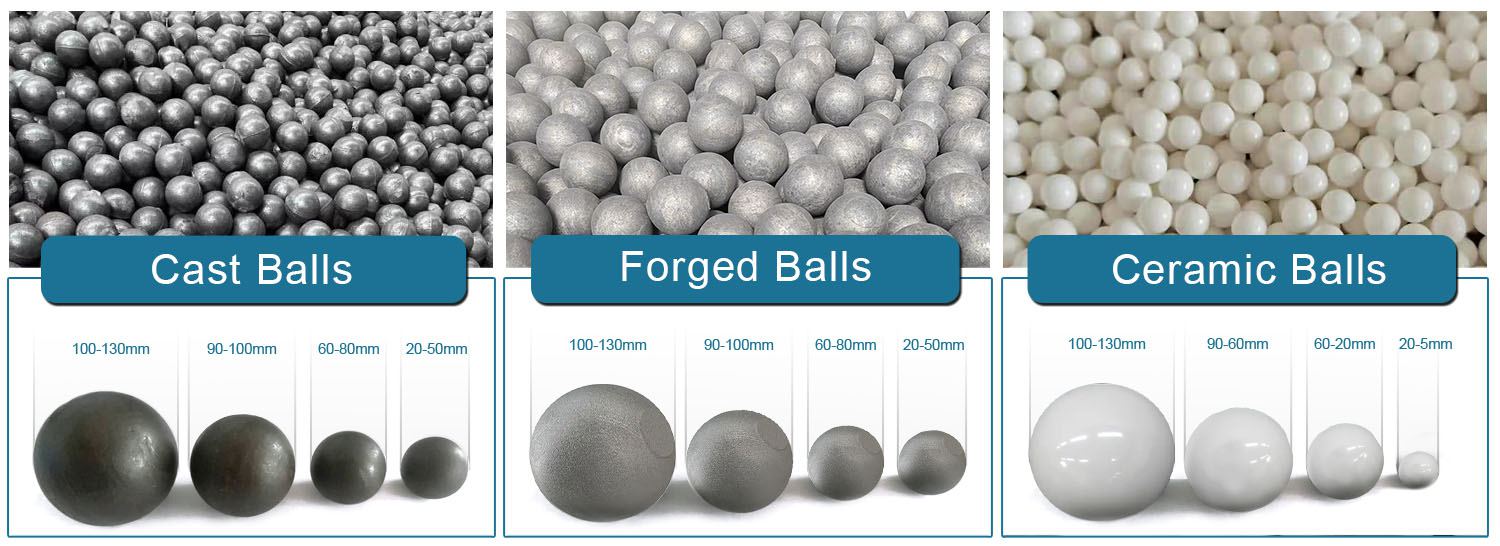

Grinding Ball

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

Overflow mills suit fine grinding, while grate mills control coarse discharge.

Yes, with ceramic media & closed-circuit classification.

Adjust solids content (optimal: 65–75%) or use dispersants.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.