The principle of magnetic separator is to use the magnetic difference of various ores or materials to separate them under the action of magnetic force and other forces. It is mainly used in various metallurgical mines to separate magnetic fine particles or remove magnetic minerals mixed with non-magnetic minerals. Magnetic separator is a commonly used magnetic separation equipment in iron ore processing plants. It uses water as the medium to separate fine particles of ore. Magnetic separator is mainly used for the beneficiation of ores such as magnetite, ilmenite and hematite.

| Parameters | Dry Magnetic Separation | Wet Magnetic Separation |

| Applicable Particle size | 0.1-50mm | 0.005-3mm |

| Processing Capacity | 5-200 t/h | 10-500 t/h |

| Magnetic Field Gradient | 0.5-5 T/m | 10-100 T/m |

| Power Consumption | 3-15 kW | 10-75 kW |

Please contact us for specific parameters.

The principle of magnetic separator is to use the magnetic difference of various ores or materials to separate them under the action of magnetic force and other forces. It is mainly used in various metallurgical mines to separate magnetic fine particles or remove magnetic minerals mixed with non-magnetic minerals. Magnetic separator is a commonly used magnetic separation equipment in iron ore processing plants. It uses water as the medium to separate fine particles of ore. Magnetic separator is mainly used for the beneficiation of ores such as magnetite, ilmenite and hematite.

Magnetic separators come in many varieties, the most basic being categorized by magnetic field strength (Gauss). Our industrial-grade magnetic separators provide over 99% metal recovery for recycling, mining and waste operations. Designed for heavy-duty performance, our systems ensure higher purity output, reduced equipment wear and tear, and increased profitability.

Why Choose Our Magnetic Separators?

✔ Superior Recovery - Up to 99.9% recovery of ferrous metals

✔ Low Maintenance - Self-cleaning design minimizes downtime

✔ Custom Configuration - Tailored to your specific material flow

✔ Energy Efficient - Optimized design reduces power consumption

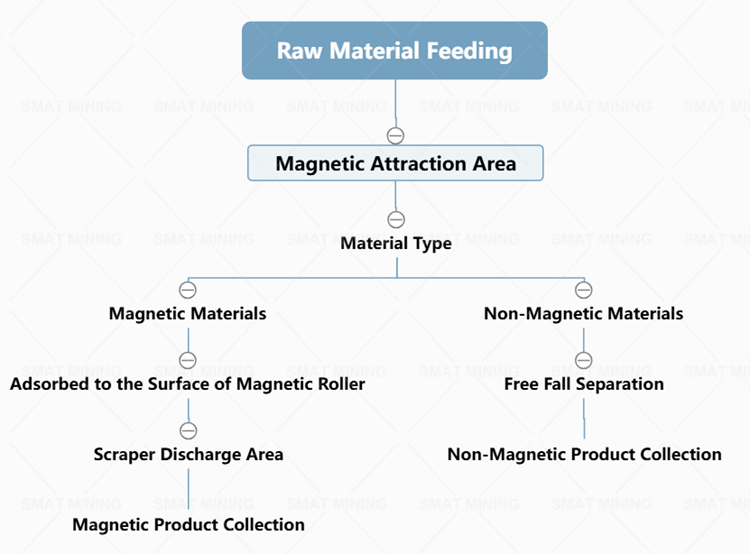

Working Principle of Magnetic Separator:

1. Slurry feeding:

The slurry enters the magnetic separator through the feed box, and under the action of the water flow of the feed water pipe, the ore particles enter the feed area of the magnetic separator in a loose state.

2. Magnetic field effect:

A magnetic field is generated inside the magnetic separator, and the magnetic minerals are adsorbed to the surface of the magnetic roller under the action of the magnetic field force.

3. Magnetic mineral separation:

Non-magnetic or weakly magnetic minerals flow out of the magnetic separator with the slurry and become tailings.

4. Concentrate recovery:

The magnetic minerals are brought to the unloading area under the rotation of the magnetic roller, fall off under the flushing water and enter the concentrate box to form concentrate.

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.