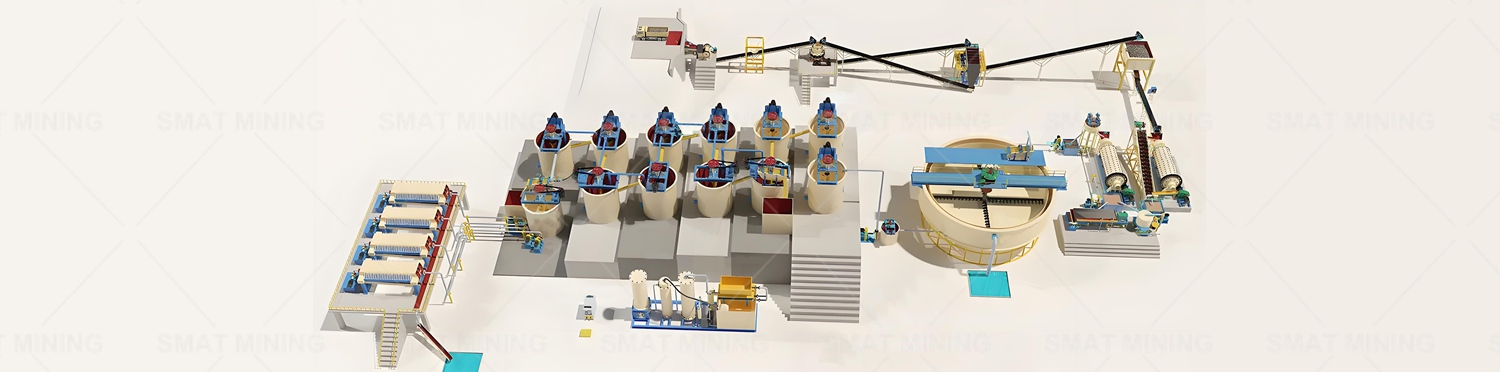

Mineral processing is a crucial step in enhancing ore grade and reducing smelting costs. We offer comprehensive solutions covering the entire process, including flotation, magnetic separation, gravity separation, and electrostatic separation, for minerals such as gold, copper, iron, lithium, and rare earths. Our services help mining enterprises increase recovery rates, lower energy consumption, and reduce pollution.

Based on the differences in the physical and chemical properties of the mineral surface (hydrophilicity, floatability), after being treated with flotation reagents, the useful minerals are selectively attached to the bubbles, achieving the purpose of separation.

The re-selection method is used to separate minerals based on the differences in their relative densities (commonly referred to as specific gravity). Mineral particles with different densities are affected by fluid dynamics and various mechanical forces in the moving medium, creating appropriate loose stratification and separation conditions, thereby enabling the separation of minerals of different densities.

The process of separation carried out by taking advantage of the magnetic differences among various ores or materials, under the influence of magnetic force and other forces.

| Model | Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging Size(mm) |

Capacity (t/h) |

Power (KW) |

Total weight (t) |

|

| φ900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 | |

| φ900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 | |

| φ1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 | |

| φ1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 | |

| φ1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 | |

| φ1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 | |

| φ1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 | |

| φ1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 | |

| φ1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 | |

| φ1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 | |

| φ1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 | |

| φ1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 | |

| φ2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 | |

| φ2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 | |

| φ2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 | |

| φ2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 | |

| φ2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 | |

| φ2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 | |

| φ2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 | |

| φ2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 | |

| φ2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 | |

| φ2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 | |

| φ2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 | |

| φ3200×4500 | 18 | 65 | <25 | 0.074-0.4 | 按工艺定 | 630 | 149 | |

| φ3600×4500 | 17 | 90 | <25 | 0.074-0.4 | 按工艺定 | 850 | 169 | |

| φ3600×6000 | 17 | 110 | <25 | 0.074-0.4 | 按工艺定 | 1250 | 198 | |

| φ3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 | |

| φ4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 | |

| φ4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 | |

| φ4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 | |

| φ4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 | |

| φ5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 | |

| φ5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 | |

| φ5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 | |

| Dry Grid Ball Mill | |||||

| Model | Cylinder | Effective Volume (m³) | Ball Loading (t) | Main Motor (kW) | |

| Diameter (mm) | Length (mm) | ||||

| 1557 | 1500 | 5700 | 8.5 | 12 | 130 |

| 1564 | 1500 | 6400 | 9.6 | 13 | 155 |

| 1864 | 1830 | 6400 | 15 | 20 | 210 |

| 1870 | 1830 | 7000 | 16 | 22 | 245 |

| 1880 | 1830 | 8000 | 18.8 | 26 | 280 |

| 2170 | 2100 | 7000 | 22 | 30 | 320 |

| 2175 | 2100 | 7500 | 23.5 | 33 | 355 |

| 2265 | 2200 | 6500 | 22 | 35 | 380 |

| 2270 | 2200 | 7000 | 23.8 | 38 | 380 |

| 2275 | 2200 | 7500 | 25.5 | 42 | 450 |

| 2470 | 2400 | 7000 | 28 | 52 | 570 |

| 2480 | 2400 | 8000 | 32 | 60 | 630 |

| 2750 | 2700 | 5000 | 25.8 | 54 | 630 |

| 2760 | 2700 | 6000 | 31 | 65 | 710 |

| Wet Grid Ball Mill | |||||

| Model | Cylinder | Effective Volum (m³) | Ball Loading (t) | Main Power | |

| Diameter (mm) | Length (mm) | ||||

| MOS-1530 | 1500 | 3000 | 4.5 | 9 | 110 |

| MQS-1545 | 1500 | 4500 | 6.7 | 14 | 155 |

| MQS-1830 | 1830 | 3000 | 6.7 | 14 | 155 |

| MQS-1845 | 1830 | 4500 | 10.5 | 20 | 210 |

| MQS-2130 | 2100 | 3000 | 8.8 | 18 | 210 |

| MQS-2136 | 2100 | 3600 | 11 | 22.5 | 245 |

| MQS-2145 | 2100 | 4500 | 13.8 | 28 | 280 |

| MQS-2230 | 2200 | 3000 | 10 | 20 | 210 |

| MQS-2245 | 2200 | 4500 | 15.2 | 30.5 | 320 |

| MQS-2430 | 2400 | 3000 | 12 | 25 | 280 |

| MQS-2436 | 2400 | 3600 | 14 | 29 | 320 |

| MQS-2445 | 2400 | 4500 | 17.8 | 37 | 380 |

| MQS-2470 | 2400 | 7000 | 28 | 58 | 480 |

| MQS-2736 | 2700 | 3600 | 18 | 38 | 400 |

| MQS-2740 | 2700 | 4000 | 20.6 | 43 | 450 |

| MQS-2745 | 2700 | 4500 | 23.2 | 48 | 480 |

| MQS-2750 | 2700 | 5000 | 25.8 | 54 | 560-630 |

| MQS-2760 | 2700 | 6000 | 31 | 65 | 630-710 |

| MQS-3040 | 3000 | 4000 | 25.7 | 54 | 560-630 |

| MQS-3064 | 3000 | 6400 | 40.2 | 84 | 1000 |

| MQS-3230 | 3200 | 3000 | 21.8 | 46 | 500 |

| MQS-3236 | 3200 | 3600 | 26.2 | 56 | 630 |

| MQS-3245 | 3200 | 4500 | 32 | 65 | 800 |

| MQS-3254 | 3200 | 5400 | 38 | 80 | 1000 |

| MQS-3640 | 3600 | 4000 | 36 | 75 | 1000 |

| MQS-3645 | 3600 | 4500 | 40.8 | 88 | 1250 |

| MQS-3650 | 3600 | 5000 | 46 | 96 | 1400 |

| MQS-3660 | 3600 | 6000 | 54 | 117 | 1400-1600 |

| MQS-4050 | 4000 | 5000 | 58 | 121 | 1500 |

| MQS-4060 | 4000 | 6000 | 70 | 146 | 1800 |

| MQS-4560 | 4500 | 6000 | 87 | 182 | 2300 |

| Overflow Ball Mill | |||||

| Model | Cylinder | Effective Volum (m³) | Ball loading (t) | Main Motor (kW) | |

| Diameter (mm) | Length (mm) | ||||

| MQY-1530 | 1500 | 3000 | 4.5 | 8 | 90 |

| MQY-1545 | 1500 | 4500 | 6.7 | 12 | 132 |

| MQY-1830 | 1830 | 3000 | 6.7 | 12 | 130 |

| MQY-1845 | 1830 | 4500 | 10.5 | 19 | 180 |

| MQY-2130 | 2100 | 3000 | 9.2 | 16 | 210 |

| MQY-2136 | 2100 | 3600 | 11 | 20 | 210 |

| MQY-2145 | 2100 | 4500 | 13.8 | 25 | 280 |

| MQY-2230 | 2200 | 3000 | 10 | 18.5 | 210 |

| MQY-2245 | 2200 | 4500 | 15.2 | 28 | 280 |

| MQY-2430 | 2400 | 3000 | 12 | 22 | 245 |

| MQY-2436 | 2400 | 3600 | 14 | 26 | 280 |

| MQY-2445 | 2400 | 4500 | 17.8 | 30 | 320 |

| MQY-2460 | 2400 | 6000 | 24 | 44 | 480 |

| MQY-2736 | 2700 | 3600 | 18 | 33 | 400 |

| MQY-2740 | 2700 | 4000 | 20.6 | 38 | 400 |

| MQY-2745 | 2700 | 4500 | 23.2 | 43 | 480 |

| MQY-2750 | 2700 | 5000 | 25.8 | 48 | 500 |

| MQY-2760 | 2700 | 6000 | 31 | 57 | 630 |

| MQY-3040 | 3000 | 4000 | 25.7 | 47 | 500 |

| MQY-3064 | 3000 | 6400 | 40.2 | 74 | 800 |

| MQY-3245 | 3200 | 4500 | 32 | 59 | 630 |

| MQY-3254 | 3200 | 5400 | 38 | 73 | 800 |

| MQY-3270 | 3200 | 7000 | 50.6 | 93 | 1250 |

| MQY-3645 | 3600 | 4500 | 40.8 | 75 | 1000 |

| MQY-3650 | 3600 | 5000 | 46 | 86 | 1250 |

| MQY-3660 | 3600 | 6000 | 54 | 102 | 1250 |

| MQY-3685 | 3600 | 8500 | 79 | 131 | 1800 |

| MQY-4060 | 4000 | 6000 | 70 | 126 | 1500 |

| MQY-4067 | 4000 | 6700 | 78 | 136 | 1600 |

| MQY-4361 | 4270 | 6100 | 80 | 144 | 1850 |

| MQY-4564 | 4500 | 6400 | 95 | 172 | 2000 |

| MQY-5064 | 5030 | 6400 | 120 | 216 | 2600 |

| MQY-5083 | 5030 | 8300 | 152 | 266 | 3300 |

| MQY-5585 | 5500 | 8500 | 187 | 338 | 4500 |

Mineral processing is a crucial step in enhancing ore grade and reducing smelting costs. We offer comprehensive solutions covering the entire process, including flotation, magnetic separation, gravity separation, and electrostatic separation, for minerals such as gold, copper, iron, lithium, and rare earths. Our services help mining enterprises increase recovery rates, lower energy consumption, and reduce pollution.

Cutting-edge flotation & magnetic separation systems boost recovery rates by 15-30%.

30+ years of mineral processing experience across 50 countries.

Low-toxicity reagents and 90% water recycling for sustainable operations.

Tailored flowsheets for unique ore types and production goals.

customized design, selection consultation

installation and commissioning, technical training

spare parts supply, remote technical support

SMAT is a leading global manufacturer of mining machinery and industrial equipment, specializing in the research, development, production and sales of mining crushing machinery, grinding machinery, mineral processing equipment, ball press equipment and generator sets. With efficient, durable and energy-saving equipment as its core competence, the company is committed to providing customers with comprehensive mining, material processing and industrial solutions.

Flotation works for sulfide ores (Cu, Pb, Zn) & oxides, using chemicals to attach minerals to bubbles. Magnetic separation targets iron, titanium, or rare earth ores with magnetic fields.

Precise grinding fineness, Custom reagent formulas, High-efficiency equipment, Automated control systems

Modular plants (50–200t/day, assembled at our factory) Containerized units (plug-and-play, tested before shipping) Gravity separation kits (shaker tables & spirals we manufacture)