SMAT Mine, a leading manufacturer of high-performance grinding balls for ball mill applications. With 20 years of expertise in the grinding media industry, we specialize in delivering durable, cost-effective solutions tailored to mining, cement, and mineral processing operations worldwide.

Diameters (mm)

Material

Material

| Ball Diameter(mm) | Weight per ball(kg) | Pcs per Ton |

| 20 | 0.034 | 31056 |

| 25 | 0.063 | 15873 |

| 30 | 0.11 | 9091 |

| 40 | 0.26 | 3891 |

| 50 | 0.51 | 2000 |

| 60 | 0.86 | 1153 |

| 70 | 1.37 | 729 |

| 80 | 2.05 | 487 |

| 90 | 2.9 | 345 |

| 100 | 4 | 250 |

| 110 | 5.3 | 188 |

| 120 | 6.8 | 147 |

| 125 | 7.75 | 129 |

| 130 | 8.74 | 74 |

The grinding efficiency and quality of ball mills largely depend on the selection of grinding media. Suitable grinding media not only improves production efficiency but also significantly reduces operating costs. Wrong media selection can lead to increased energy consumption, product contamination, and accelerated equipment wear.

Our professional technical team can provide you with optimized grinding media proportioning solutions based on factors such as your material hardness, particle size requirements, and production targets, ensuring your ball mill always operates in optimal condition.

●Grinding efficiency improved by 30-50%, energy consumption reduced by 20-35%;

●Professional proportioning solutions, precisely matching your material characteristics;

●Excellent wear resistance, service life extended by over 40%;

●Superior contamination control, reducing iron content pollution in products.

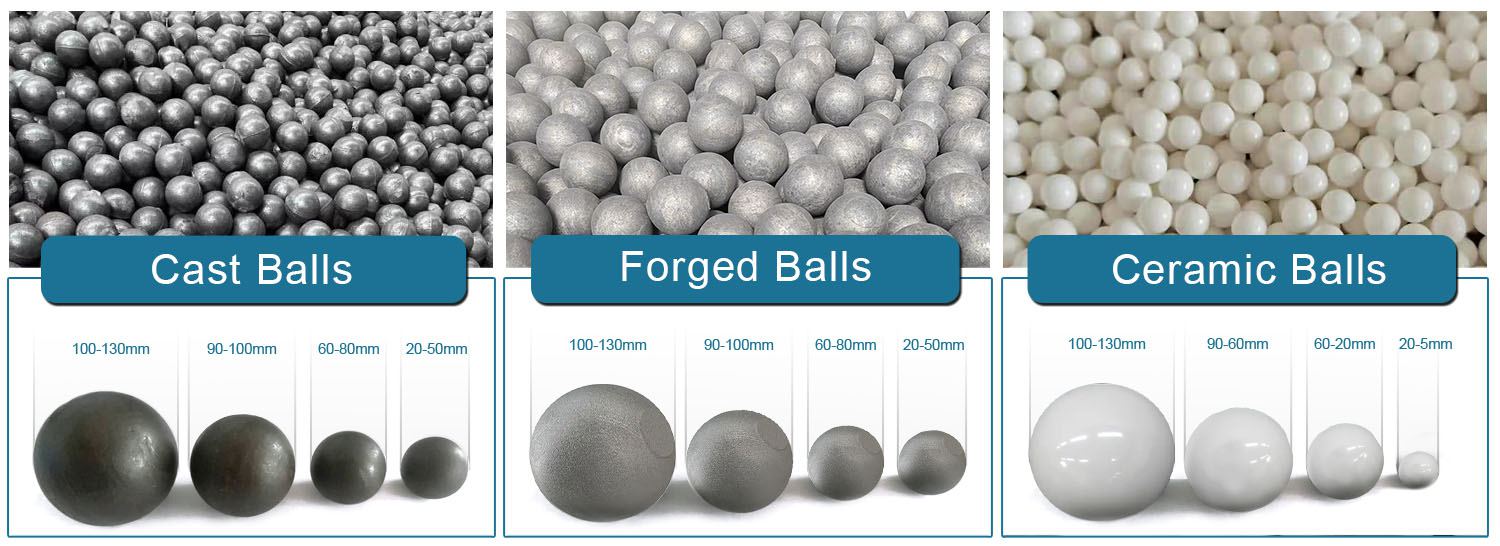

Our Product

| Media Type | Main Advantages | Investment Cost | Service Life |

| High-Chrome Steel Balls | High hardness (HRC60-66) | Medium | 6-12 Month |

| 3x more wear resistant than ordinary steel balls | |||

| Breakage rate below 0.5% | |||

| Strong corrosion resistance | |||

| Low-Chrome Steel Balls | High cost-effective | Lower | 3-6 Month |

| 20-30% lower procurement cost | |||

| Better wear resistance than forged balls | |||

| Complete specifications, customizable | |||

| Alumina Ceramic Balls | Zero metal contamination | High | 12-24 Month |

| Good chemical stability | |||

| Acid and alkali corrosion resistant | |||

| High density, good grinding efficiency | |||

| Mineral Processing, Cement Production, Ceramic Glazes, Coal Powder Preparation | |||

Professional Technical Services

Our engineering team provides professional media proportioning optimization services, offering scientific steel ball grading solutions by analyzing your material characteristics, mill parameters and product requirements.

Services include:

Proportion configuration of steel balls of different sizes

Accurate calculation of filling rate

Determination of ball replenishment cycle and quantity

Solutions for balancing energy consumption and efficiency

Let our grinding media experts provide you with free mill evaluation and media proportioning solutions to help you achieve cost reduction and efficiency improvement goals!

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

SMAT is a leading global manufacturer of mining machinery and industrial equipment, specializing in the research, development, production and sales of mining crushing machinery, grinding machinery, mineral processing equipment, ball press equipment and generator sets. With efficient, durable and energy-saving equipment as its core competence

We usually accept T/T in advance, and L/C for large sums. If you prefer other payment terms, please vdiscuss them.