MTW series EURO grinding mill is updated powder grinding equipment researched by SMAT Machinery. With the good performance of large capacity, low power consumption, reasonable structure, it can greatly meet the client's requirements on fine powder production.

Max Feeding Size

Output Size

Capacity

| Model | MTW110 | MTW138 | MTW175 | MTW215 | |||

| Roller Size (L×H)(mm) |

360×210 | 460×260 | 520×300 | 640×340 | |||

| Grind Ring Inner Dia. (mm) |

φ1100×210 | φ1380×260 | φ1750×300 | φ2150×340 | |||

| Main Roller Speed (r/min) |

120 | 96 | 75 | 65 | |||

| Max Feeding Size (mm) |

30 | 35 | 40 | 50 | |||

| Output Size (mm) |

1.6-0.038 | 1.6-0.038 | 1.6-0.038 | 1.6-0.045 | |||

| Capacity (t/h) |

3-10 | 6-20 | 10-35 | 20-50 | |||

| Power(Kw) | Main Grinder |

75 | 90 | 185 | 280 | ||

| Powder classifier |

7.5 | 11 | 30 | 45 | |||

| Blower | 75 | 90 | 185 | 280 | |||

| Overall Dimension (mm) |

8425×7933×8642 | 10920×9470×10227 | 12195×9555×9916 | 13922×9810×13226 | |||

Our MTW European grinding mills combine European engineering principles with global performance standards to provide superior grinding efficiency. Designed for applications with high precision and rugged construction, these grinding mills set a new benchmark in grinding technology. Perfectly meets the production needs of customers with fine powders ranging from 80-425 mesh.

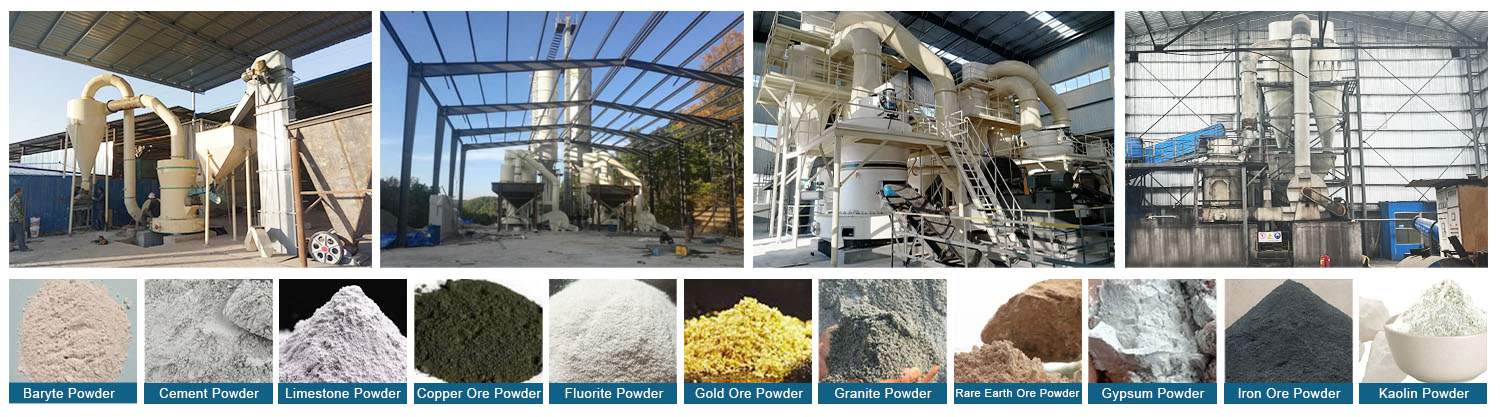

Application areas: cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic minerals, building materials, ceramics

MTW Series EURO Grinding Mill Advantage:

The high-end configuration of bevel gear integrated transmission, frequency conversion classification, andisolated powder collection greatly improves the effi-ciency of powder selection.

Automatic thin oil lubrication+water-cooled con-stant temperature system ensures stable andreliable equipment, increasing its lifespan by 5-10times.

Automatic control: The electrical system adopts centralized control, the grinding workshop can be operated unmanned, and maintenance is simple and convenient.

High grinding efficiency: The fan and analyzer control the fineness, eliminate screens and blockages, and produce uniform powder (80-325 mesh) with a pass rate of more than 99%.

Reduce costs: Drying and grinding are integrated into one, no separate dryer is required, and investment is reduced.

Sturdy and durable: The mill is equipped with an integrated gearbox, anti-vibration system, and components such as grinding rings with a service life of up to 8,000 hours and grinding rollers with a service life of up to 6,000 hours, with a designed service life of more than 30 years.

Environmental protection: The grinding process adopts a negative pressure closed-loop circulation system to minimize dust and noise. A full pulse dust collector is used, and the dust removal rate reaches 99%.

Low energy consumption: Small footprint, high powder making efficiency, and energy consumption is reduced by more than 60% compared with ball mills.

Working principle:

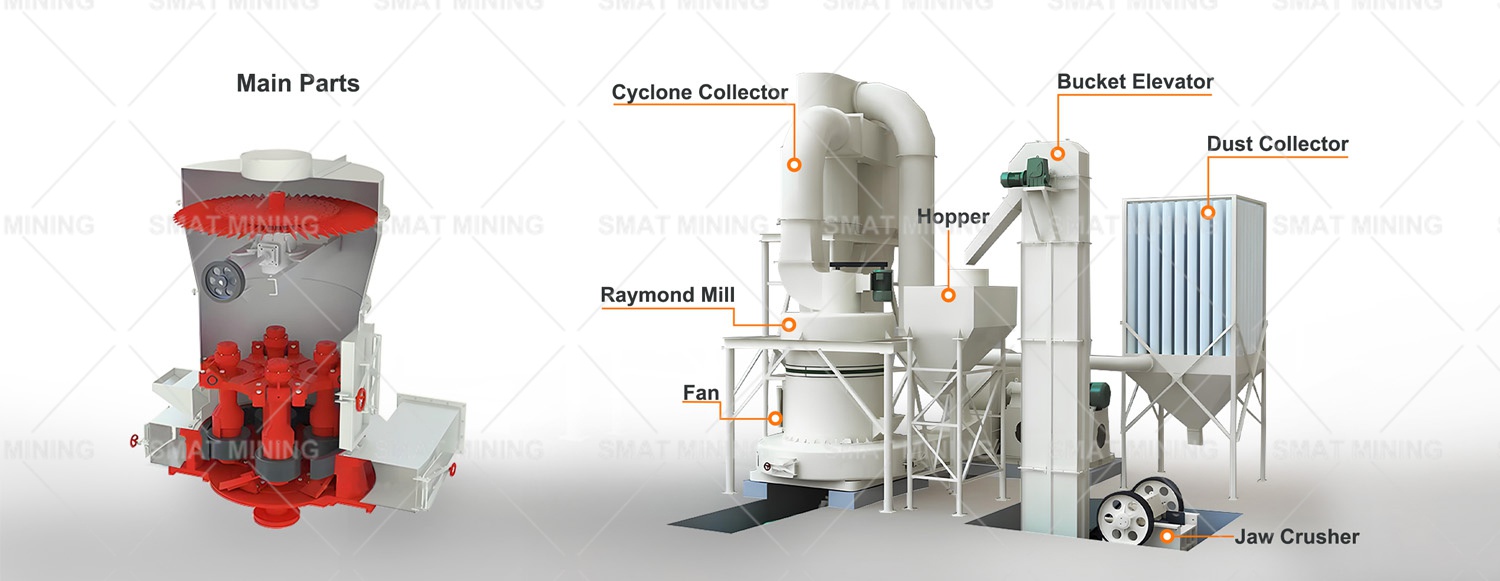

Feeding: After the material is processed by the crusher, it is evenly and quantitatively fed into the grinding chamber of the mill through the variable frequency belt feeder.

Grinding: After the material enters the grinding chamber, it is gradually ground into fine powder by the high-speed rotation impact and friction of the grinding roller and the grinding ring.

Classification: The ground material rises with the airflow generated by the fan and enters the powder selector for classification. The selector screens the material according to the particle size, and the material with qualified fineness passes, while the coarse particles return to the grinding chamber for re-grinding.

Collection: The qualified fine powder after classification is collected by the cyclone powder collector to separate the air.

Discharge: The collected fine powder is discharged from the mill through the discharge device to complete the entire grinding process.

During the entire working process, the European version of the mill uses efficient air selection technology and precise classification system to ensure the grinding efficiency and fineness control of the material. At the same time, the internal thin oil lubrication system and dust removal device ensure the stable operation and environmental protection requirements of the equipment.

Raymond Mill vs MTW EURO Grinding Mill vs YGM Grinding Mill

| Standard Raymond Mill | (MTW Series EURO Grinding Mill) | (YGM High-Pressure Grinding Mill) | |

| Fineness | 80-325Mesh | 80-400Mesh | 60-1000Mesh (Customizable) |

| Capacity | 0.5-60t/h | 0.5-60t/h | 0.4-16t/h |

| Airflow Design | Straight, Prone to clogging | Curved, Energy-efficient | Optimized for fine powder |

| Investment Cost | Lowest | 30%-40% higher | 20%-30% higher than MTW |

| Applications | limestone, gypsum, marble, dolomite, kaolin, diatomite, silicate,slag,flyash etc. | barite, limestone, ceramics, slag etc. | |

Why choose our Raymond mill?

SMAT Raymond Mill vs. Traditional Mills

Energy consumption is 30-50% lower than standard mills

Fineness: 80-600 mesh

Noise: <75dB, 85-95dB

Maintenance: easy to repair, complex operation

Other Advantages:

✓ Durable components - roller life exceeds 8000 hours

✓ Intelligent control - touch screen PLC system

✓ Global service - fast spare parts delivery

Our service:

Installation - on-site guidance provided

Training - operator and maintenance programs

Support - 24/7 technical hotline

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.