Our Ball Mill is designed to deliver exceptional performance, durability, and precision. With advanced technology and robust engineering, this machine is the ultimate choice for achieving superior grinding results and maximizing productivity.

Max Ball Load(t)

Feeding Size(mm)

Capacity

| Ball Loading(t) | Effective Volum(m³) | Main Motor(kw) | |

| Dry Grid Ball Mill | 12-65 | 8.5-31 | 130-710 |

| Wet Grid Ball Mill | 9-182 | 4.5-87 | 110-2300 |

| Overflow Ball Mill | 8-338 | 4.5-187 | 90-4500 |

| Model | Shell rotation speed (r/min) |

Ball load (t) |

Feeding size (mm) |

Discharging Size(mm) |

Capacity (t/h) |

Power (KW) |

Total weight (t) |

|

| φ900×1800 | 36-38 | 1.5 | <20 | 0.075-0.89 | 0.65-2 | 18.5 | 5.85 | |

| φ900×3000 | 36 | 2.7 | <20 | 0.075-0.89 | 1.1-3.5 | 22 | 6.98 | |

| φ1200×2400 | 36 | 3 | <25 | 0.075-0.6 | 1.5-4.8 | 30 | 13.6 | |

| φ1200×3000 | 36 | 3.5 | <25 | 0.074-0.4 | 1.6-5 | 37 | 14.3 | |

| φ1200×4500 | 32.4 | 5 | <25 | 0.074-0.4 | 1.6-5.8 | 55 | 15.6 | |

| φ1500×3000 | 29.7 | 7.5 | <25 | 0.074-0.4 | 2-5 | 75 | 19.5 | |

| φ1500×4500 | 27 | 11 | <25 | 0.074-0.4 | 3-6 | 110 | 22 | |

| φ1500×5700 | 28 | 12 | <25 | 0.074-0.4 | 3.5-6 | 130 | 25.8 | |

| φ1830×3000 | 25.4 | 11 | <25 | 0.074-0.4 | 4-10 | 130 | 34.5 | |

| φ1830×4500 | 25.4 | 15 | <25 | 0.074-0.4 | 4.5-12 | 155 | 38 | |

| φ1830×6400 | 24.1 | 21 | <25 | 0.074-0.4 | 6.5-15 | 210 | 43 | |

| φ1830×7000 | 24.1 | 23 | <25 | 0.074-0.4 | 7.5-17 | 245 | 43.8 | |

| φ2100×3000 | 23.7 | 15 | <25 | 0.074-0.4 | 6.5-36 | 155 | 45 | |

| φ2100×4500 | 23.7 | 24 | <25 | 0.074-0.4 | 8-43 | 245 | 56 | |

| φ2100×7000 | 23.7 | 26 | <25 | 0.074-0.4 | 12-48 | 280 | 59.5 | |

| φ2200×4500 | 21.5 | 27 | <25 | 0.074-0.4 | 9-45 | 280 | 54.5 | |

| φ2200×6500 | 21.7 | 35 | <25 | 0.074-0.4 | 14-26 | 380 | 61 | |

| φ2200×7000 | 21.7 | 35 | <25 | 0.074-0.4 | 15-28 | 380 | 62.5 | |

| φ2200×7500 | 21.7 | 35 | <25 | 0.074-0.4 | 15-30 | 380 | 64.8 | |

| φ2400×3000 | 21 | 23 | <25 | 0.074-0.4 | 7-50 | 245 | 58 | |

| φ2400×4500 | 21 | 30 | <25 | 0.074-0.4 | 8.5-60 | 320 | 72 | |

| φ2700×4000 | 20.7 | 40 | <25 | 0.074-0.4 | 22-80 | 380 | 95 | |

| φ2700×4500 | 20.7 | 48 | <25 | 0.074-0.4 | 26-90 | 480 | 102 | |

| φ3200×4500 | 18 | 65 | <25 | 0.074-0.4 | 按工艺定 | 630 | 149 | |

| φ3600×4500 | 17 | 90 | <25 | 0.074-0.4 | 按工艺定 | 850 | 169 | |

| φ3600×6000 | 17 | 110 | <25 | 0.074-0.4 | 按工艺定 | 1250 | 198 | |

| φ3600×8500 | 18 | 131 | <25 | 0.074-0.4 | 45.8-256 | 1800 | 260 | |

| φ4000×5000 | 16.9 | 121 | <25 | 0.074-0.4 | 45-208 | 1500 | 230 | |

| φ4000×6000 | 16.9 | 146 | <25 | 0.074-0.4 | 65-248 | 1600 | 242 | |

| φ4000×6700 | 16.9 | 149 | <25 | 0.074-0.4 | 75-252 | 1800 | 249 | |

| φ4500×6400 | 15.6 | 172 | <25 | 0.074-0.4 | 84-306 | 2000 | 280 | |

| φ5030×6400 | 14.4 | 216 | <25 | 0.074-0.4 | 98-386 | 2500 | 320 | |

| φ5030×8300 | 14.4 | 266 | <25 | 0.074-0.4 | 118-500 | 3300 | 403 | |

| φ5500×8500 | 13.8 | 338 | <25 | 0.074-0.4 | 148-615 | 4500 | 525 | |

Are you looking for a reliable, efficient, and cost-effective solution for grinding and processing materials in your mining, cement, or industrial operations? Our Ball Mill is designed to deliver exceptional performance, durability, and precision. With advanced technology and robust engineering, this machine is the ultimate choice for achieving superior grinding results and maximizing productivity.

Classification of SMAT Ball Mill:

Grinding Media: Ball mill, Rod mill and SAG Mill(without grinding media)

Material Discharging Mode: Wet grid mil, Dry grid mill and Overflow mill

Driving Mode: Side and Central driving, the former is more popular now

Driving Configuration:

1. Asynchronous Motor Driving: Asynchronous Motor+Reducer+ Pinion+Girthgear

2. Synchronous Motor Driving: Synchronous Motor+Air Cluth+ Pinion+Girthgear.

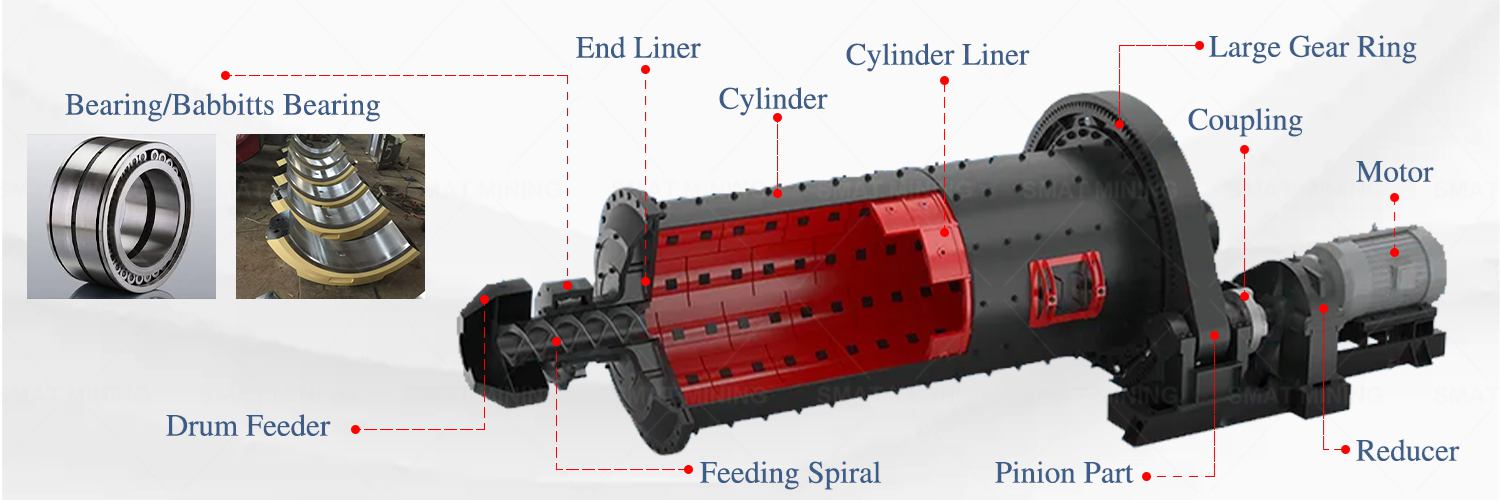

Internal Structure:

1. Main bearing, adopting slide bearing, rolling bearing or sliding-shoe bearing as per requirement.

2. Liner, adopting wear-resistant mental liner, rubber liner, magnetic liner and alumina liner (high aluminum lining brick).

3. Following items as per options: inching driving device, high and low pressure lubrication station, spraying lubrication device of gear, jacking device and PLC control system.

We specialize in both dry and wet process ball mills engineered for optimal performance across industries. Our solutions are customized for your specific material characteristics and production requirements.

Dry Process Ball Mill Solutions

Cement production, Ceramic powders, Dry mineral processing,Coal pulverization

Wet Process Ball Mill Solutions

Mineral ore processing, Metal powder slurry, Industrial chemical processing

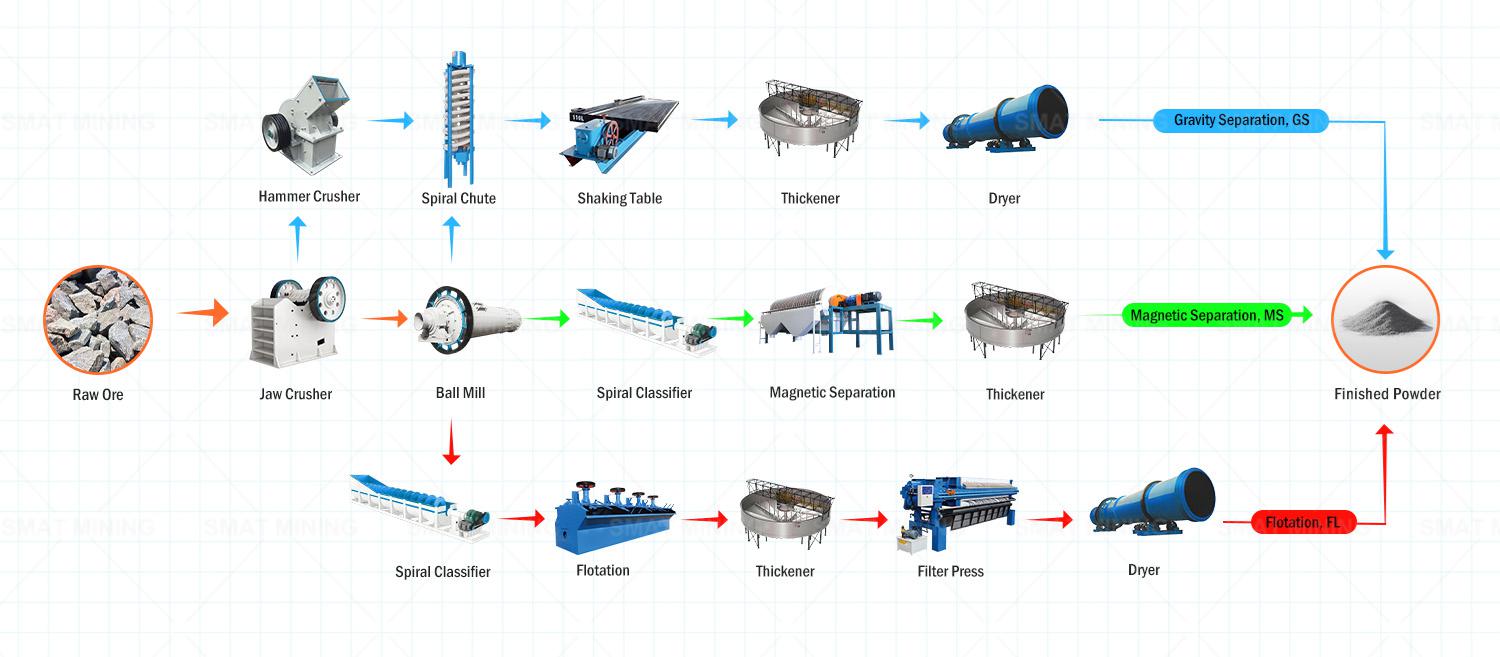

Flotation Separating Process

Flotation process equipment consists of jaw crusher, ball mill, classifier, main equipment such as mixing drum, flotation machine, thickener and dryer, with the feeder, elevator, belt conveyor can be composed of a complete flotation line. The production line has high efficiency, low energy and processing high quantity, reasonable economy and other advantages.

Magnetic Separating Process

The magnetic separation process of the new beneficiation production line consists of jaw crusher and ball mill machine, classifier, magnetic separator, thickener and dryer, etc. Ready, with the miner, elevator, belt conveyor can be composed complete magnetic separation production line. The production line has high efficiency, low energy, high processing capacity, economic and reasonable advantages. According to the actual situation of customers condition design supporting equipment.

Why Choose Our Ball Mill?

Superior Grinding Performance:

Our ball mill ensures efficient and uniform grinding of materials, delivering consistent particle size and quality.

Versatility for Multiple Applications:

Ideal for grinding materials like ore, cement, ceramics, and chemicals, our ball mill adapts to a wide range of industries and applications.

Durable and Reliable Design:

Built with high-quality materials and heavy-duty components, our ball mill is designed to withstand harsh operating conditions, ensuring long-lasting performance.

Low Maintenance and Operational Costs:

With a simple design and minimal moving parts, maintenance is quick and hassle-free, reducing downtime and saving you money.

Energy-Efficient Operation:

Our ball mill is optimized for low energy consumption, helping you reduce operational costs while maintaining high efficiency.

Customizable Solutions:

We offer tailored configurations, including size, capacity, and speed adjustments, to meet your specific grinding needs, ensuring the perfect fit for your operations.

Safe and Smooth Operation:

Equipped with safety features like emergency stop buttons and protective guards, our ball mill ensures a safe working environment for operators.

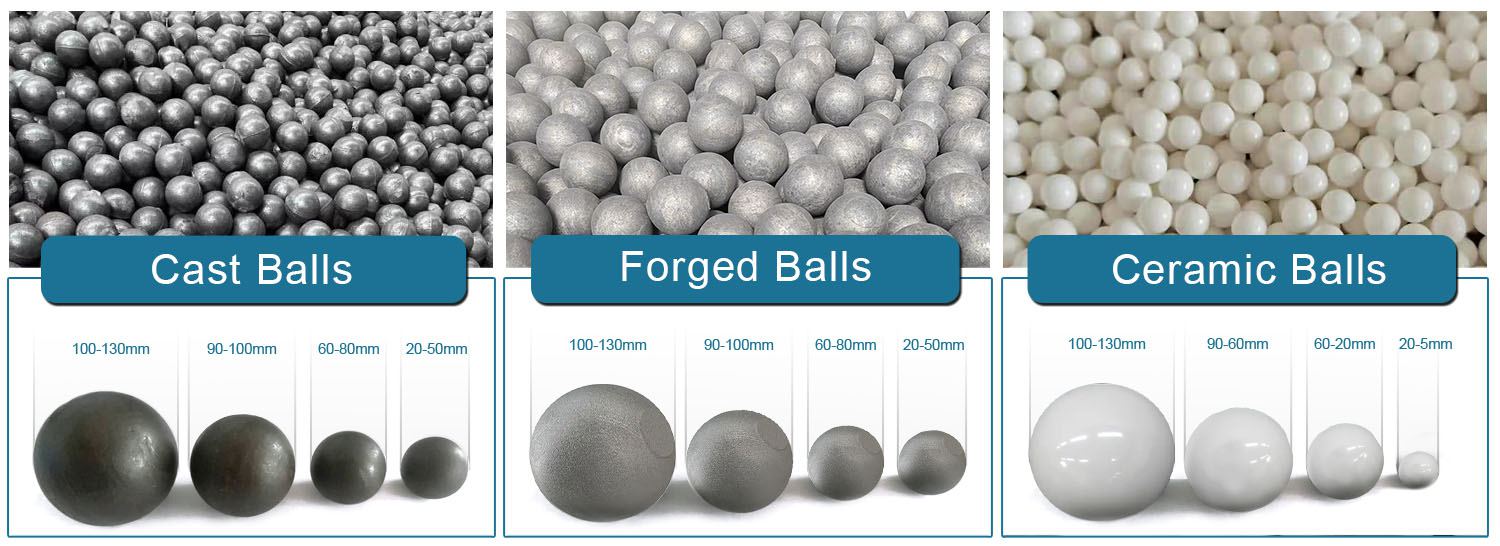

Grinding Ball

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.