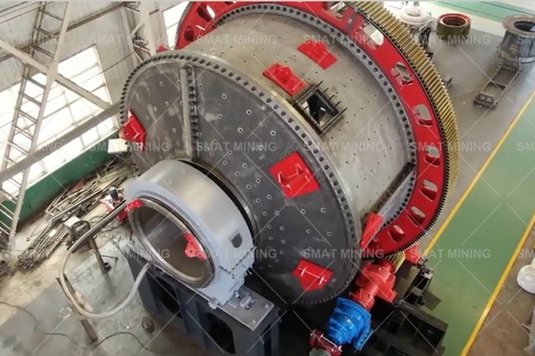

SAG (Semi-autogenous grinding) mill is a large-scale grinding equipment that combines the self-crushing of ore with the assistance of a small amount of steel balls. Its distinctive feature is the use of the ore itself as the main grinding medium, supplemented by a small amount of steel balls (usually accounting for 8%-15% of the mill capacity) to improve efficiency.

Volume(m³)(t)

Speed(r/min)

Main Motor(kw)

| Model | Cylinder | Effective volume(m³) | Speed(r/min) | Main Motor(kw) | |

| Diameter(mm) | Length(mm) | ||||

| SM-2410 | 2400 | 1000 | 4.5 | 22 | 55 |

| SM-3212 | 3200 | 1200 | 9.2 | 18.2 | 160 |

| SM-4014 | 4000 | 1400 | 16.6 | 17.6 | 245 |

| SM-5518 | 5500 | 1800 | 34.6 | 15 | 800 |

| SM-6433 | 6400 | 3300 | 107 | 13 | 2000 |

| SM-6724 | 6700 | 2400 | 80.5 | 13 | 2000 |

| SM-7525 | 7500 | 2500 | 107 | 11.4 | 2500 |

SAG (semi-autogenous grinding) mill is a large-scale grinding equipment that combines ore self-crushing with a small amount of steel balls. Its main feature is to use the ore itself as the main grinding medium, supplemented by a small amount of steel balls (usually 8%-15% of the mill capacity) to improve efficiency.

Working Principle of SAG mill

1. Feeding

Ore (particle size can reach 250-300 mm) is fed into the rotating drum through a conveying system. The inside of the mill is lined with lifters (wavy linings) to help the ore and steel balls stack.

2. Rotation and lifting

The drum rotates at 70%-80% of the critical speed driven by the motor. Centrifugal force lifts the ore and steel balls until gravity causes them to fall freely.

3. Grinding mechanism

The falling ore/steel balls collide with the bottom material to break the coarse particles. The friction between the ore fragments gradually produces finer particles. Steel balls can also act on minerals with higher hardness and are not easy to self-grind.

4. Discharge and classification

The ground slurry is discharged through the discharge grate or overflow for further processing (such as flotation). Oversized materials remain in the slurry for further grinding.

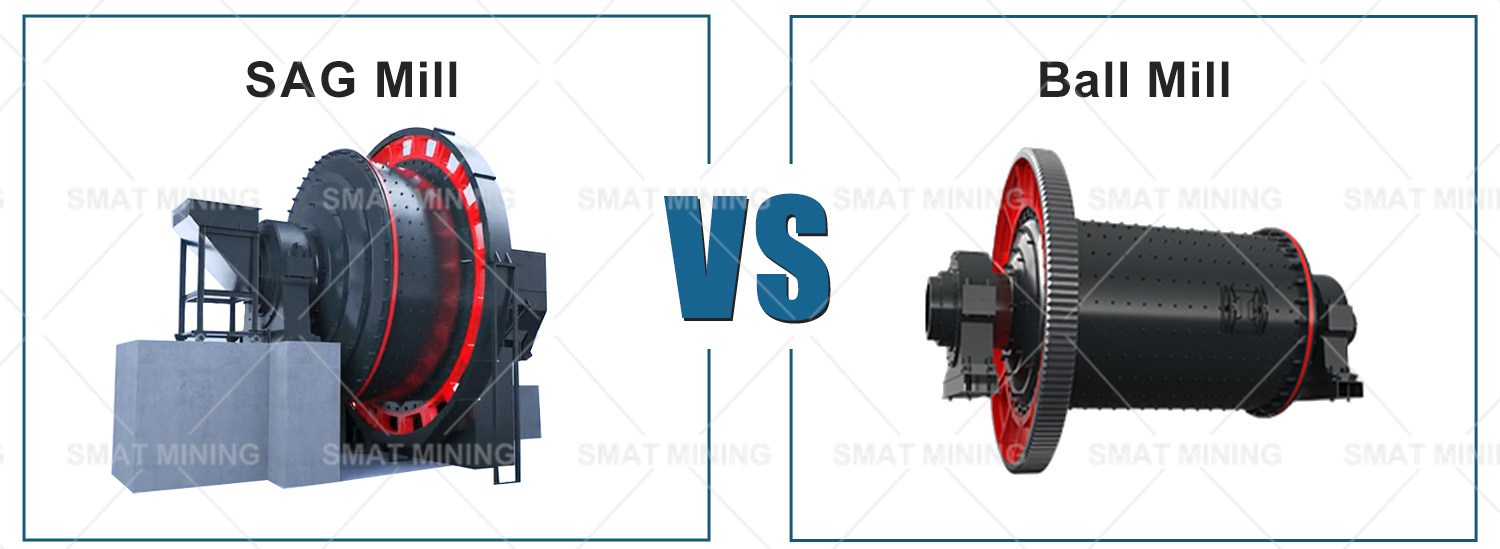

SAG MILL VS BALL MILL

In the field of grinding and mineral processing, semi-autogenous grinding mills (SAG) and ball mills are two of the most widely used equipment. Although both are used to reduce the particle size of ores, they have significant differences in operation, efficiency and application. Let's learn about the differences between them today. Choose the best option for your project.

| Feature | SAG Mill | Ball Mill |

| Grinding Mechanism | Uses ore itself as grinding media (along with some steel balls) | Relies entirely on steel balls for grinding |

| Feed Size | Handles larger rocks (up to 300mm) | Requires finer feed (typically <25mm) |

| Energy Efficiency | Higher power consumption but reduces need for crushing stages | Lower energy use but requires pre-crushing |

| Media Cost | Fewer steel balls needed (lower media cost) | Higher steel ball consumption |

| Application | Primary grinding in large-scale mining | Secondary grinding, fine milling |

Advantages of SAG Mills:

SAG mills can process large rocks directly without multiple crushing steps. So they are more suitable for soft ores to medium hardness ores: compared with ball mills, less or no grinding media is required, reducing costs.

Advantages of Ball Mills:

Ball mills have precise grinding control and are more suitable for fine grinding and uniform particle size. It has a simpler design, so the investment cost is lower. With different liners, it can be used for wet or dry grinding. It can handle hard ores that are difficult for SAG mills to handle.

Mining Applications:

SAG mills: Best for primary grinding of gold, copper and platinum ores, where the ores are relatively soft. Usually used in conjunction with ball mills.

Ball mill: used for secondary grinding, cement production, and processing of harder ores such as iron.

How to Choose for your Project?

Large-scale, high-volume operations → SAG mill (with ball mill for fine grinding).

For fine grinding, harder ores, or smaller-scale operations → ball mill.

For more solutions, please feel free to contact us.

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.