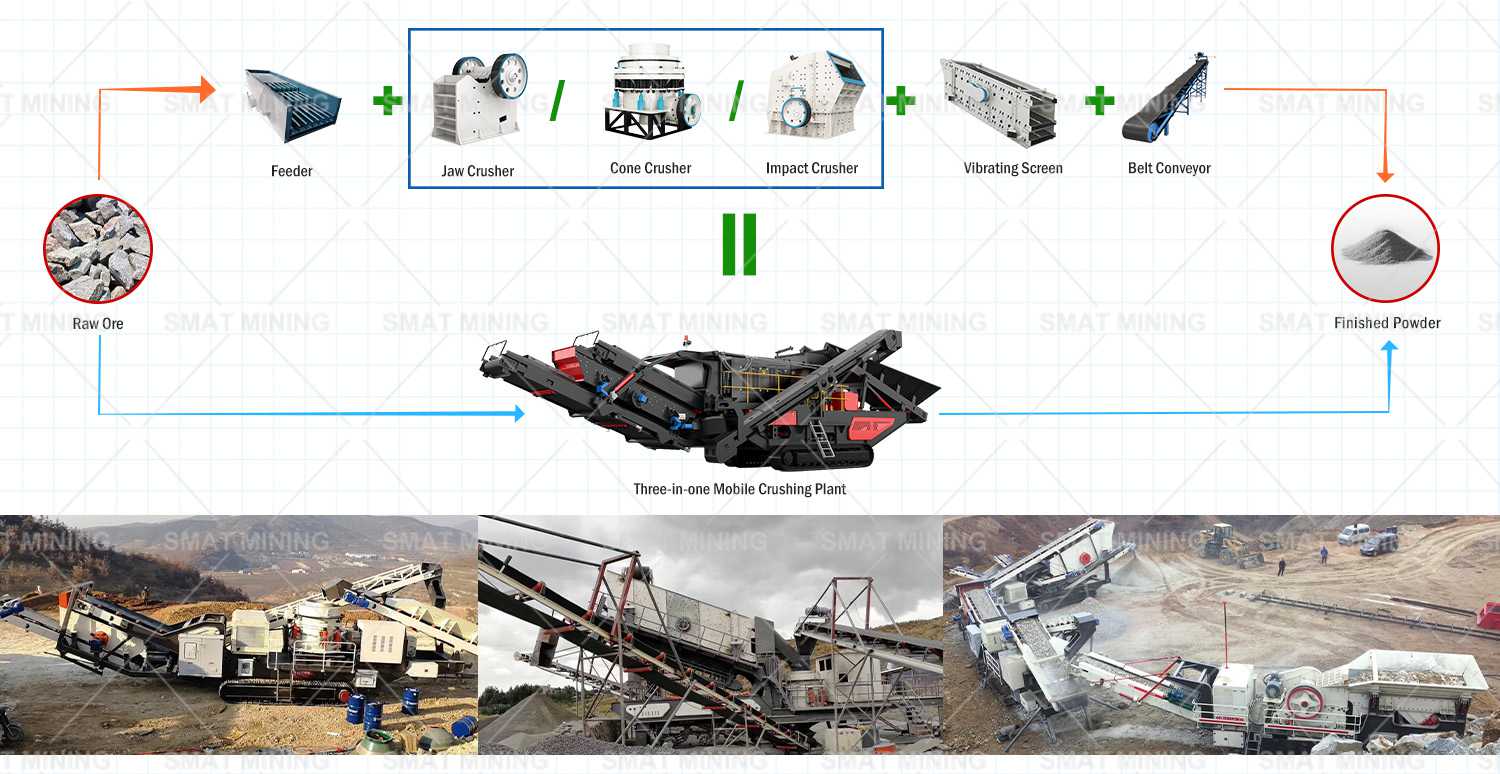

Explore our revolutionary 3-in-1 mobile crushing station solution. Integrating feeding, crushing, and screening, it is designed for mining, quarrying, and C&D recycling, offering unparalleled mobility, rapid deployment, and significantly lower operating costs. Get a custom solution now!

| Parameter | Options & Range |

| Mobile Chassis Type | Tracked / Wheeled |

| Core Crusher | Jaw Crusher / Impact Crusher / Cone Crusher |

| Feed Type | Vibrating Feeder |

| Screen System | Single / Double / Triple Deck Vibrating Screen |

| Production Capacity | 50 - 400 t/h |

| Final Product Specifications | 0-5mm, 5-10mm, 10-20mm, 20-31.5mm, etc. |

| Power System | Diesel Generator / External Electric Power |

Why 3-in-1?

The All-in-One Solution That Surpasses Tradition

Choosing a crushing solution is a strategic decision that impacts your project timelines, budgets, and overall profitability. Traditional stationary plants, while powerful, lock you into a single location with immense initial investment in infrastructure and installation.

Our 3-in-1 Mobile Crushing Station liberates your operations from these constraints. Its core value lies in the innovative integration of the three previously independent key processes - feeding, crushing and screening - into a compact and robust mobile chassis. This integrated approach means you are investing in a complete system, not just a machine. This rapid deployment capability is invaluable for contractors handling multiple short-term projects or working in remote areas where setting up a fixed plant is impractical and cost-prohibitive.

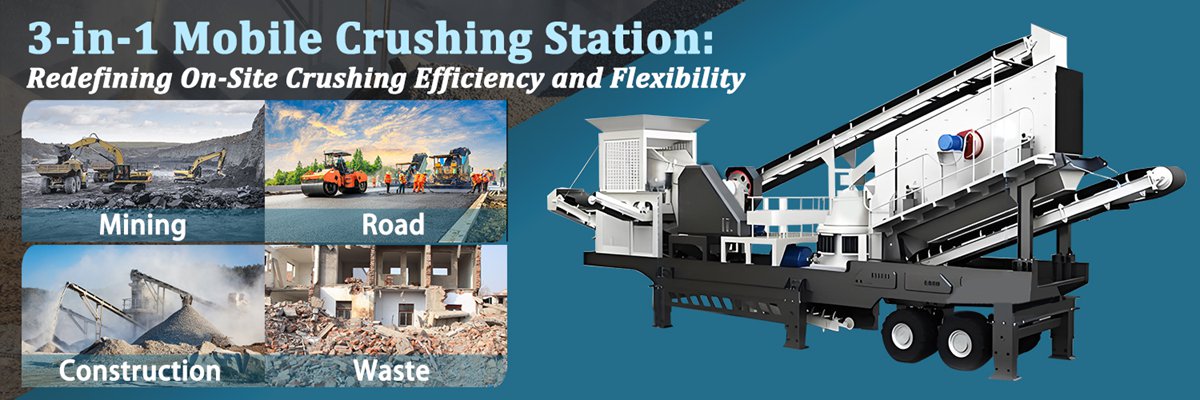

Wide Application:

From Mining to Economy

The true power of a versatile machine lies in the diversity of challenges it can overcome. Our three-in-one mobile crushing plant is a powerful, versatile machine suitable for a wide range of applications.

In mining and quarrying, it can be used for primary crushing or crushing and screening of medium-hardness ores. It is particularly suitable for trial mining and small-scale mining at the edge of a mining area, or for supplementary crushing for large fixed production lines, effectively reducing mining costs.

In infrastructure construction, such as highway, railway, and water conservancy projects, temporary quarries are set up at different sections of the road or the excavation of tunnel excavation soil is used to produce roadbed materials. Our mobile plant can keep pace with project schedules, enabling local material collection, processing, and application, significantly reducing material transportation costs and construction time.

Most importantly, it plays an irreplaceable role in the recycling of construction and demolition waste, making it a key piece of technical equipment in the development of a circular economy. In urban renewal and demolition and reconstruction projects, the equipment can be driven directly onto the site to crush and screen discarded concrete, bricks, asphalt blocks and other construction waste to produce renewable aggregate (RCA), which can be used to prepare recycled bricks, road base layers or recycled concrete, truly turning waste into treasure.

SMAT TEAM & Customer:

We look forward to providing you with the most professional crushing plant solutions. If you need specific material crushing solutions, please feel free to contact our technical team.

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.