SMAT 4-in-1 mobile crushing plant is a powerful, flexible and portable crushing solution designed for mining, quarrying and construction applications. It adopts three optimized configurations (jaw crusher + cone crusher, jaw crusher + impact crusher and jaw crusher + fine jaw crusher), equipped with corresponding feeders and screening, reducing conveyor belts, while also meeting various material processing needs and providing a new generation of intelligent and excellent performance.

Mobility: crawler or wheeled, easy to transport

Capacity: 20-150 tons/hour (depending on demand)

Automation: intelligent control system with remote monitoring

Please contact us for detailed parameters.

Why Choose Four in One Mobile Crushing Station:

•Fully mobile, easy to relocate, no fixed installation required

•Adaptable host equipment switching to meet customer personalized needs

•Reduce conveyor belts, reduce costs, while meeting the same configuration production efficiency

•Reduce material transportation costs

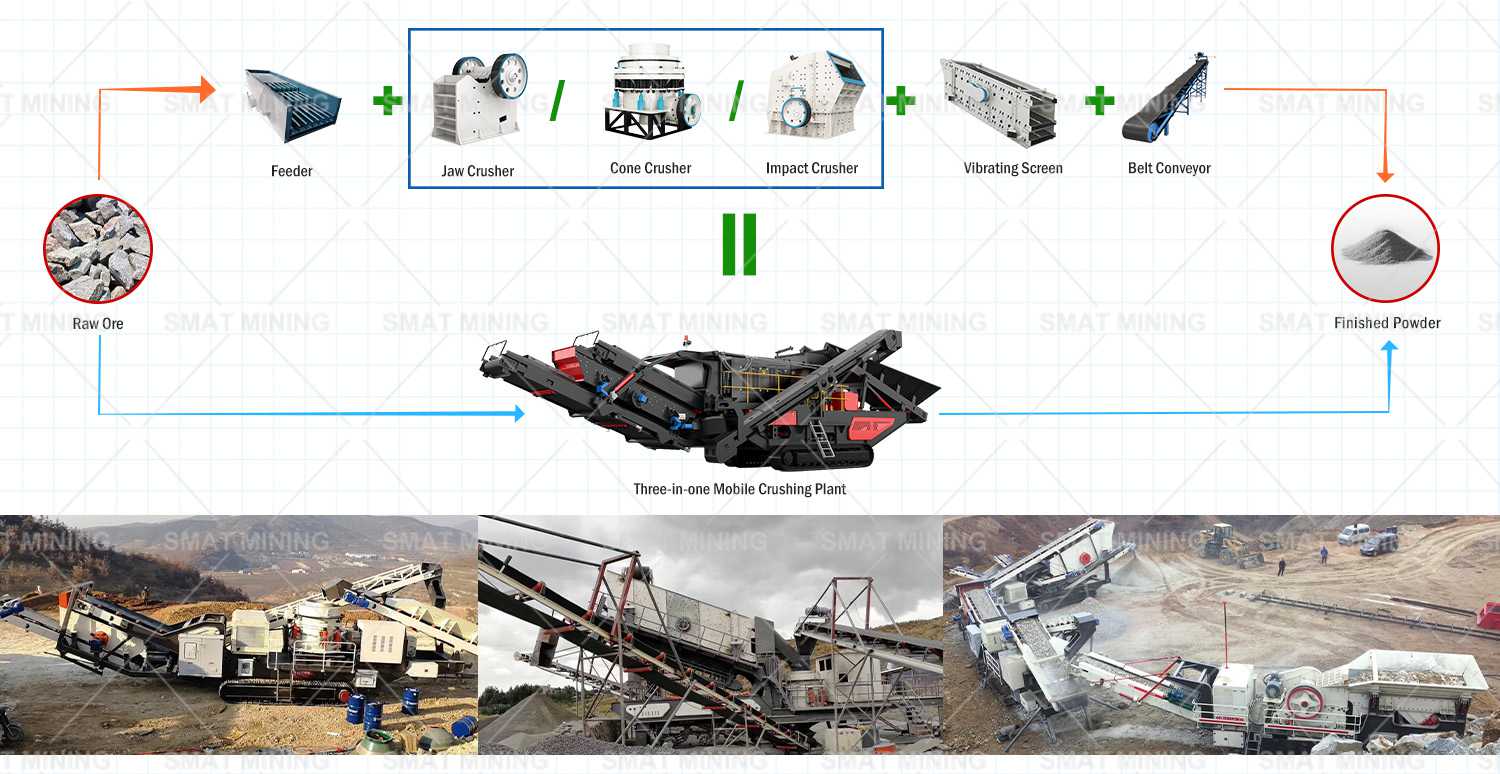

Three-in-one Mobile Crushing Station:

Feeder + crusher + screen: single chassis solution, with 50% less floor space. Suitable for urban reconstruction, narrow areas, and small and medium-sized sand and gravel aggregate yards. The overall procurement cost is also reduced by 25-30%.

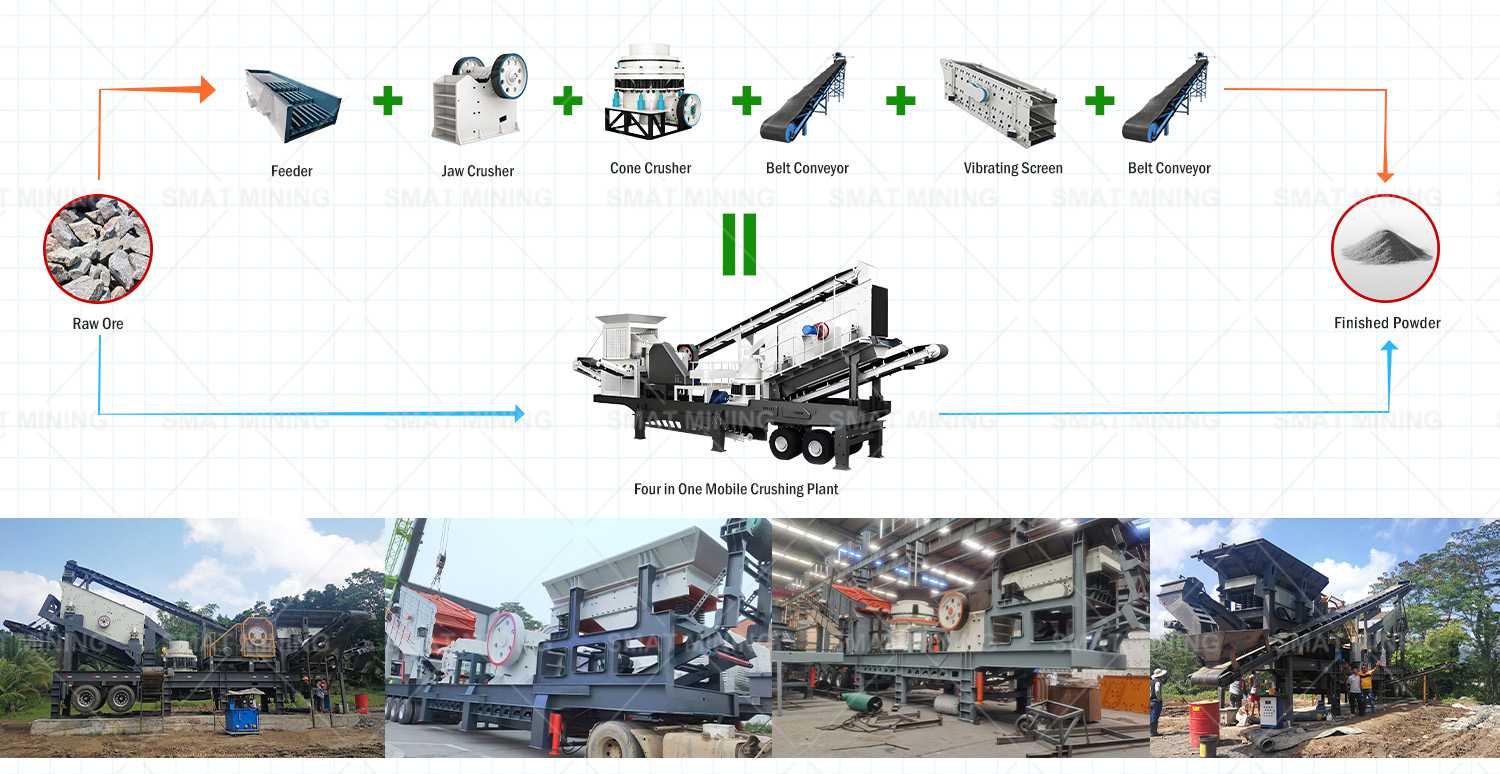

Four-in-one Mobile Crushing Station:

A single machine completes five equipment functions: feeder + primary crushing + secondary crushing + screening + return system. Manpower requirements are reduced by 60%. It can operate continuously to avoid the production capacity fluctuations caused by the abbreviated feeding of loaders in traditional solutions.

Recommended solutions:

Option 1: Feeder + Jaw Crusher + Cone Crusher + Screening

Best suited for: hard and abrasive materials (granite, basalt, iron ore)

Crushing stages: primary (jaw) + secondary (cone) for finer output

Discharge particle size: adjustable, as fine as 0-20 mm

Option 2: Feeder + Jaw Crusher + Impact Crusher + Screening

Best suited for: medium hardness materials (limestone, recycled concrete, asphalt)

Crushing stages: primary (jaw) + secondary (impact) for cubic aggregates

Discharge particle size: 0-40 mm (suitable for construction) (aggregates)

Option 3: Feeder + Jaw Crusher + Fine jaw crusher + screening

Applicable to: high-precision crushing (quarry, mineral processing)

Crushing level: primary crushing (jaw) + fine crushing (secondary jaw), uniform particle size

Discharge particle size: 0-20 mm (suitable for sand and fine aggregate)

SMAT TEAM & Customer:

We look forward to providing you with the most professional crushing plant solutions. If you need specific material crushing solutions, please feel free to contact our technical team.

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.