Our Raymond mills (Raymond roller mills) are high-performance, fine powder processing machines for a wide range of industries. With proven reliability and energy-efficient operation, our mills are able to achieve precise control of particle sizes from 80-600 mesh. Raymond mills (also known as Raymond roller mills) are vertical structure grinding machines that have become the industry standard for dry powder processing of medium-hard non-metallic minerals. SMAT Raymond mills (Raymond roller mills) are high-performance, fine powder processing machines for a wide range of industries. With proven reliability and energy-efficient operation, our mills are able to achieve precise control of particle sizes from 80-600 mesh.

Max Feeding Size

Output Size

Capacity

| Model | SM3R2115 | SM3R2615 | SM3R2715 | SM3R3016 | SM4R3216 | SM5R4121 | SM6R4427 |

| Roller Number | 3 | 3 | 3 | 3 | 4 | 5 | 6 |

| Roller Diameter (mm) | 210 | 260 | 270 | 300 | 320 | 410 | 440 |

| Roller Height (mm) | 150 | 150 | 150 | 160 | 160 | 210 | 270 |

| Ring Diameter (mm) | 630 | 780 | 830 | 880 | 970 | 1280 | 1600 |

| Ring Height (mm) | 150 | 150 | 150 | 160 | 160 | 210 | 270 |

| Maximum Feed Size (mm) | 15-20 | 15-20 | 15-20 | 15-20 | 20-25 | <30 | <35 |

| Finished Powder Size (mm) | 0.044-0.165 | 0.044-0.165 | 0.044-0.165 | 0.044-0.165 | 0.044-0.165 | 0.95-0.033 | 0.95-0.033 |

| Power of the Main Frame (KW) | 15 | 18.5 | 22 | 30 | 37 | 75 | 132 |

| Power of classifier (KW) | 2.2 | 2.2 | 2.2 | 2.2 | 5.5 | 7.5 | 11 |

| Power of blower (KW) | 11 | 15 | 18.5 | 22 | 37 | 75 | 132 |

| Capacity (t/h) | 0.4-1.6 | 0.8-2.5 | 0.9-2.8 | 0.6-1.2 | 1.8-4.5 | 3-9.5 | 8-16 |

A Raymond mill (Raymond roller mill) is the most popular industrial grinding equipment for producing fine powders between 80-600 mesh. As leading Raymond mill manufacturers, we provide high-efficiency powder processing solutions for minerals, chemicals, and construction materials.

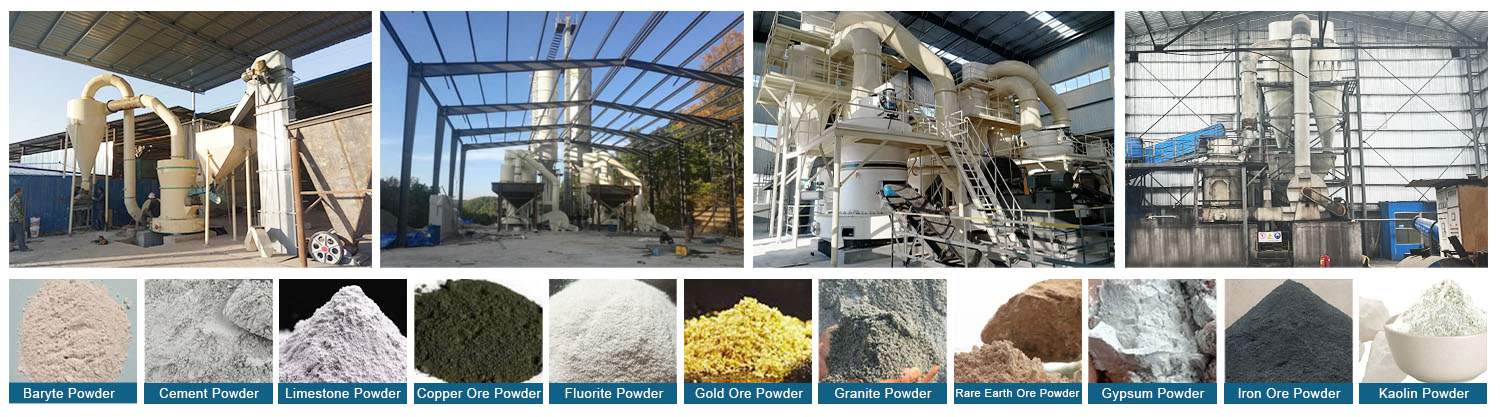

Application areas: cement, coal, power plant desulfurization, metallurgy, chemical industry, non-metallic minerals, building materials, ceramics

Key Advantage for Our Buyer Partner:

✔ Energy Saving - 30-50% lower power consumption than ball mills

✔ Precision Grinding - Adjustable particle size from 80 to 600 mesh

✔ Low Maintenance - Easy-access design reduces downtime

✔ CE Certified - Meets international safety standards

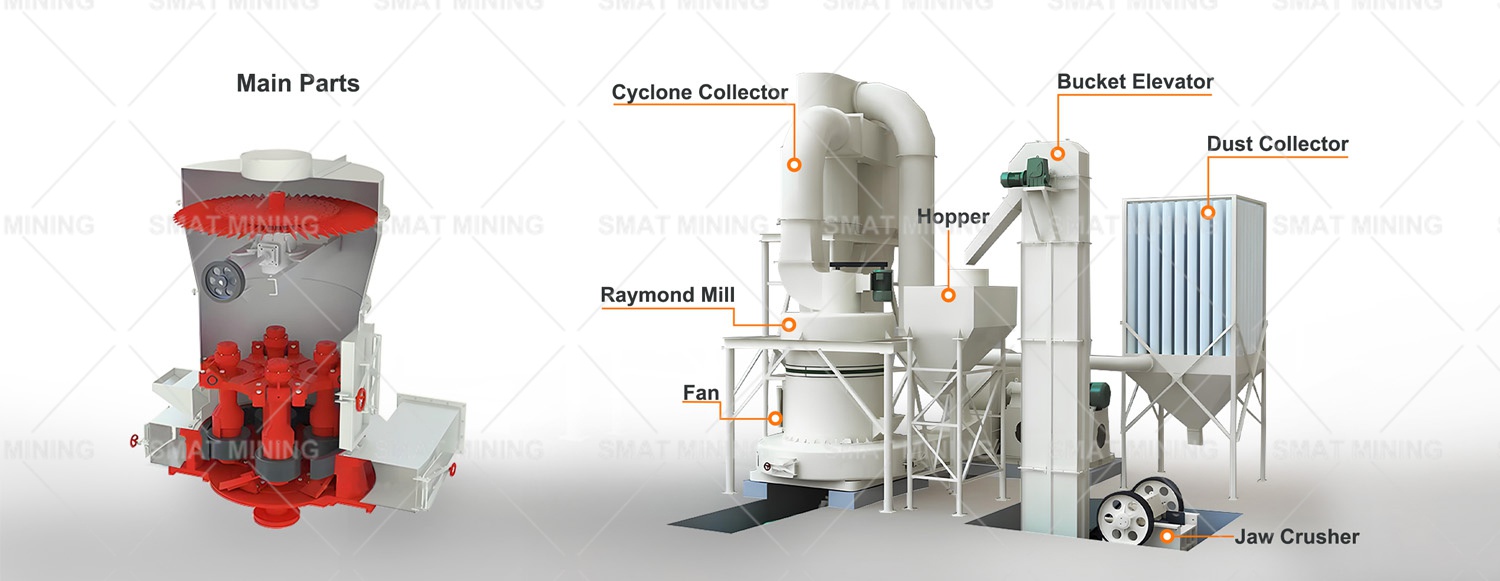

Working Principle:

Material Feeding - Uniform Feeding into the Grinding Chamber

Roller Pressing - 3-6 Rollers Grinding with a Rotating Ring

Centrifugal Classification - Precise Particle Size Separation

Air Circulation - Efficient Powder Collection System

Raymond Mill Applications - Solutions for Your Industry

Building Materials

Limestone Powder for Concrete (200-325 Mesh)

Plaster Processing for Drywall

Fly Ash Grinding for Cement Additives

Industrial Minerals

Barite Powder (API Standard 4.1+ Density)

Calcium Carbonate (Coating Grade)

Kaolin (90% Particle Size < 2μm)

Specialty Chemicals

Activated carbon regeneration

Petroleum coke grinding

Battery material processing

Raymond Mill vs MTW EURO Grinding Mill vs YGM Grinding Mill

| Standard Raymond Mill | (MTW Series EURO Grinding Mill) | (YGM High-Pressure Grinding Mill) | |

| Fineness | 80-325Mesh | 80-400Mesh | 60-1000Mesh (Customizable) |

| Capacity | 0.5-60t/h | 0.5-60t/h | 0.4-16t/h |

| Airflow Design | Straight, Prone to clogging | Curved, Energy-efficient | Optimized for fine powder |

| Investment Cost | Lowest | 30%-40% higher | 20%-30% higher than MTW |

| Applications | limestone, gypsum, marble, dolomite, kaolin, diatomite, silicate,slag,flyash etc. | barite, limestone, ceramics, slag etc. | |

Why choose our Raymond mill?

SMAT Raymond Mill vs. Traditional Mills

Energy consumption is 30-50% lower than standard mills

Fineness: 80-600 mesh

Noise: <75dB, 85-95dB

Maintenance: easy to repair, complex operation

Other Advantages:

✓ Durable components - roller life exceeds 8000 hours

✓ Intelligent control - touch screen PLC system

✓ Global service - fast spare parts delivery

Our service:

Installation - on-site guidance provided

Training - operator and maintenance programs

Support - 24/7 technical hotline

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.