As a professional manufacturer of sand production line equipment, SMAT offers customized solutions ranging from 50 to 400 tons. We transform raw materials such as granite, limestone, or river pebbles into high-quality manufactured sand that meets your local standards.

Max. Input Size

Sand Making Capacity

Sand Shaping Capacity

| Model | Max.Input Size(mm) | Sand Making Capacity (t/h) |

Sand Shaping Capacity (t/h) |

Power(Kw) | |

| Sand Making | Sand Shaping | ||||

| VSI 8015 | ≤30 | ≤40 | 109-117 | 131-140 | 75×2 |

| VS19518 | ≤35 | ≤45 | 135-147 | 165-185 | 90×2 |

| VSI 9526 | ≤40 | S50 | 167-179 | 200-215 | 132×2 |

| VSI 9532 | ≤40 | S50 | 198-210 | 232-248 | 160×2 |

| VSI 1140 | ≤45 | ≤55 | 264-283 | 317-342 | 200×2 |

| VSI 1145 | s45 | S55 | 304-325 | 366-392 | 220×2 |

| VSI 1150 | ≤45 | ≤55 | 344-368 | 413-442 | 250×2 |

| VSI 1263 | ≤50 | ≤60 | 454-486 | 545-583 | 315×2 |

As a professional manufacturer of sand production line equipment, SMAT offers customized solutions ranging from 50 to 400 tons. We transform raw materials such as granite, limestone, or river pebbles into high-quality manufactured sand that meets your local standards. Our solutions integrate crushing, shaping, screening, and cleaning technologies to produce aggregate with precise particle size distribution and adjustable particle size.

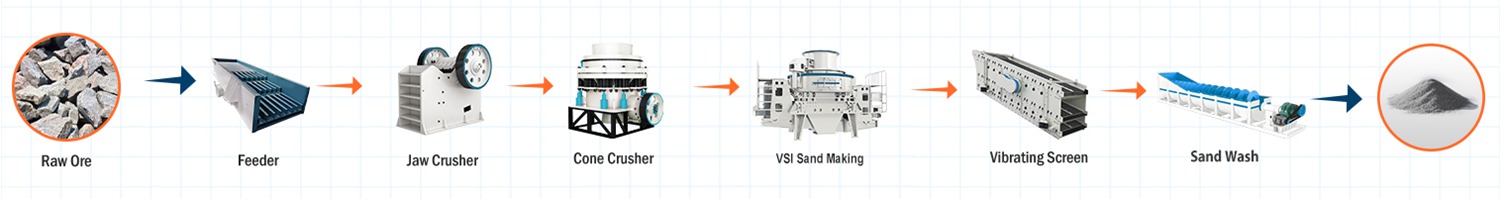

Stationary Sand Making Plant Configuration:

Raw Material Processing:

If your raw material is larger, you may consider using a primary jaw crusher to crush it to ≤60mm. Alternatively, you can use a secondary cone or impact crusher with hydraulic adjustment to further crush it to ≤30mm.

Core Process:

VSI Sand Making Crusher: Utilizes a rock-on-rock or rock-on-iron crushing method to produce cubic particles.

Other Machines:

Screening: Multi-layer vibrating screening with an efficiency exceeding 90%.

Dust Suppression: Pulse-jet bag dust collector with a dust removal efficiency exceeding 99%.

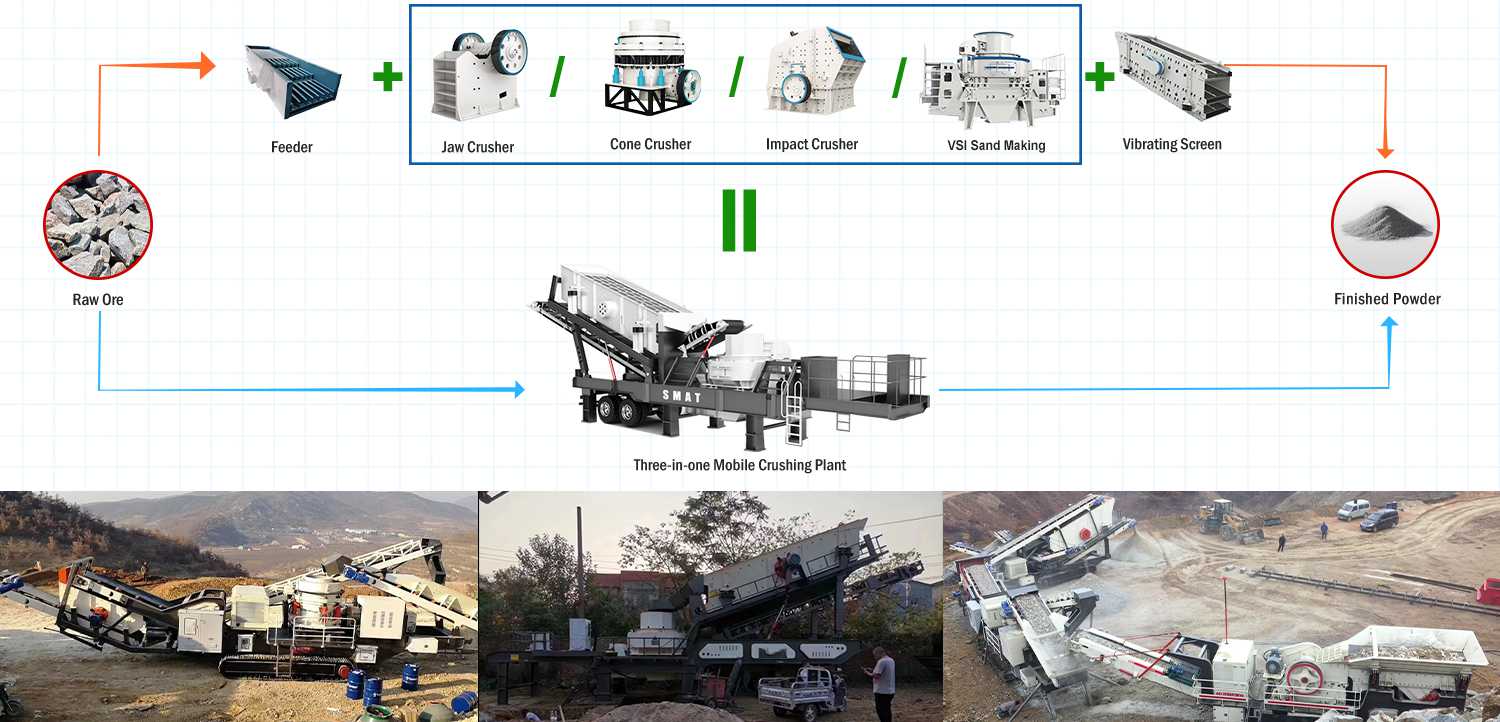

Mobile Sand Making Line Description:

Mobile sand making machine is a mobile, vehicle-mounted vertical shaft impact crusher. Compared to traditional fixed sand making machines, mobile sand making machines can replace entire production lines. Consider using a single machine in a "three-in-one" operation mode. It integrates feeding, screening, and sand making. It can also be connected to other mobile sand and gravel equipment to form a mobile sand production line, achieving higher output and adapting to a variety of stone materials.

Why Choose Our Sand Making Machine?

High-Quality Sand Production:

Our sand making machine produces uniform, well-shaped sand particles, perfect for construction, concrete, and industrial applications.

Exceptional Efficiency:

With advanced crushing and shaping technology, our machine ensures high output and low energy consumption, reducing operational costs.

Versatility for Multiple Applications:

Ideal for producing artificial sand, shaping aggregates, and processing minerals like limestone, granite, and basalt.

Durable and Reliable Design:

Built with high-strength materials and robust engineering, our machine is designed to withstand harsh operating conditions, ensuring long-lasting performance.

Easy Maintenance and Operation:

User-friendly design and accessible components make maintenance quick and hassle-free, minimizing downtime and maximizing productivity.

Environmentally Friendly:

Our sand making machine is designed to reduce waste and optimize resource utilization, making it an eco-friendly choice for sustainable operations.

Customizable Solutions:

We offer tailored configurations to meet your specific production requirements, ensuring the perfect fit for your operations.

Comparison for Construction Sand Production:

| Category | Roller Crusher | VSI Crusher | Rod Mill |

| Particle Shape | Flakiness more | Few flakiness, mainly cubical | Better particle shape, mainly cubical |

| Fineness Reference | 2-4.5 mm Coarse Sand | 2.3-5.0 mm Medium Sand | 1.6-2.2 mm Fine Sand |

| Capital Cost | Low (low initial equipment investment and low maintenance cost of wearing parts) | High (high equipment investment and high maintenance cost) | High (highest equipment investment, low maintenance cost) |

| Wear Parts | Grinding roller. Long service life and low replacement frequency | Rotor and hammer. Frequent replacement | According to the loss of steel rod |

| Maintenance Complexity | Low(only need to adjust the gap between the rollers, the discharge can be less than 5mm. Only need to adjust the roller gap regularly) | High (must be equipped with vibrating screen adjustment, high sand return, rotor dynamic balance calibration, operating experience required)) | Low (only need to replenish the steel rod regularly) |

| Feed Material | Medium hard rock (limestone, etc.) | High hard rock (granite, etc.) | Hard Rock |

| Suitable sand type | Ordinary concrete sand | High-strength concrete/Asphalt sand | Special mortar/Decorative sand |

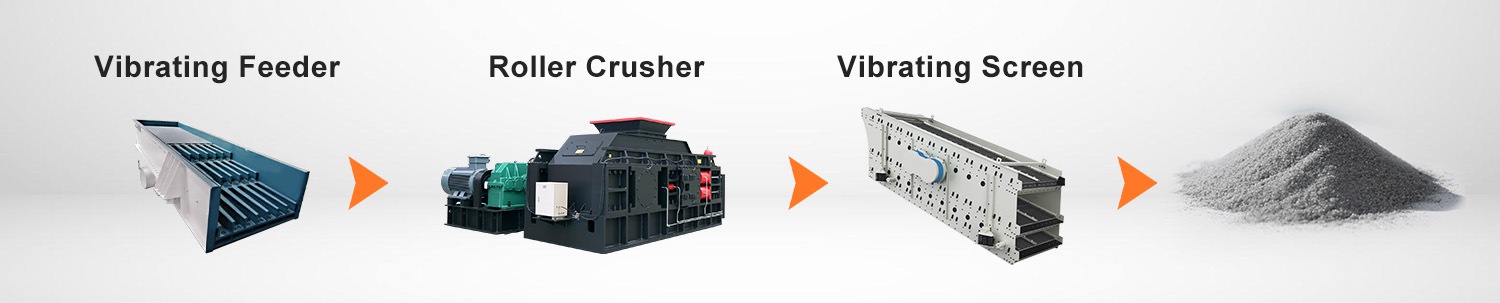

Advantages of Choosing a Roller Crusher:

1. Its compact structure, light weight, and small size can reduce space costs and are easy to operate and maintain.

2. The new equipment uses multiple protection devices and interlocking devices such as mechanical, electrical, and hydraulic devices to effectively protect the motor, crusher, and the entire system. It does not need to replace the roller body of the mill for life, while the old double roller mill needs to be disassembled for overhaul and the roller body needs to be replaced after one year of use.

3. Compared with other types of crushers, it has no requirements for the moisture content of the crushed material and is non-sticky and non-blocking.

4. Equipped with a hydraulic automatic retreat device, it can effectively prevent the feed object from damaging the tooth roller. It is also equipped with an intelligent cleaning device, which can automatically remove the adhered materials on the crusher cavity wall at working intervals.

5. Suitable for a variety of materials. It can crush brittle materials with medium and low hardness, such as bituminous coal, anthracite, lignite and coal gangue, and can also be used for sintered ore, coke, slag, shale and limestone.

SMAT Solution for Sand Making:

SMAT factory provides a variety of sand making solutions, these are the four most popular ones.

If your raw materials are of medium and low hardness, then we recommend this solution.

If your raw materials are of high hardness, you can also consider this solution.

If you pursue low cost and do not have high requirements for finished sand, we also recommend you to use this solution.

At the same time, we can also provide solutions for rod mills to make sand.

If you have more solution requirements, please contact us, and we will discuss the most suitable customized solution for you.

Provide regular maintenance plans and fast troubleshooting to address operational challenges.

Ensure the long-term availability of original spare parts to maintain stable equipment performance.

24/7 technical assistance via phone, email, or remote support to resolve issues promptly.

We provide a wide range of crushing machines, including jaw crushers, cone crushers, impact crushers, hammer crushers, and mobile crushing plants. Each type is designed for specific applications and materials.

Our machines are capable of processing various materials, including hard rock, ore, limestone, granite, basalt, recycled concrete, and more. They are suitable for mining, quarrying, and recycling operations.

The choice depends on factors like the type of material, required output size, production capacity, and operational conditions. Our team can help you select the best machine based on your specific requirements.

Yes, we offer a comprehensive range of spare parts and dedicated after-sales support to ensure your equipment operates smoothly throughout its lifespan.