EN

A leading gold mining company in Sudan aims to optimize the efficiency of its grinding circuit. The customer's existing cast balls are experiencing excessive damage (a loss of 3 - 5% per month). Each batch of processed ore requires a high consumption of 108 kilograms. Therefore, the customer's requirement is for 70mm forged steel balls for the coarse crushing of gold-bearing quartz ore.

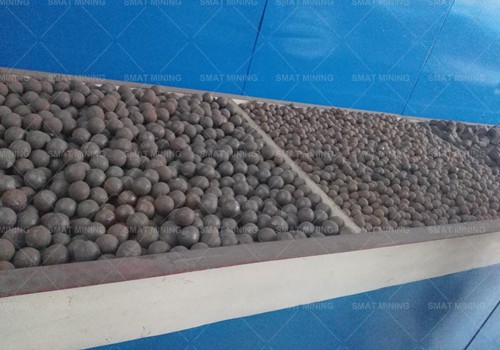

SMAT Solution: High-quality Forged Grinding Balls

We supply 70mm high-carbon forged steel balls, featuring the following characteristics:

Outstanding material properties:

Composition: 60MnCr1 (Hardness 58 - 62 Brinell hardness)

Impact toughness: ≥ 12 joules per square centimeter